Explanation

Using the hydraulic tilt mechanism and the hinge tongue, the Inkema Hinge Tongue ramp can bridge the distance and height between the loading area and the truck body.

Specifications

RH11 Dock Levellers

The RH11 Dock Leveller can bridge the distance and height between the loading bay and the lorry's body, using its hydraulic tilting mechanism and hinged lip.

Its 400mm hinged hydraulic lip is long enough to allow the dock leveller’s platform to rest firmly on the lorry’s trailer.

This type of embedded pit loading leveller can support up to 15,000 kg, with a maximum working gradient of 12.5%.

There are 4 standard sizes for the RH11 Dock Leveller, with different widths for the hinged lip. We also design and manufacture RH11 Dock Levellers up to 5000mm long x 2400 wide x 800 high*.

- L 2060 x (W 1800/2000/2200) x H 600mm

- L 2300 x (W 1800/2000/2200) x H 600mm

- L 2560 x (W 1800/2000/2200) x H 600mm

- L 3060 x (W 1800/2000/2200) x H 600mm

*For other dimensions, please consult our salesman.

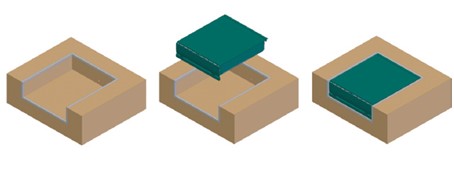

The Embedded Pit type levellers require a sub-frame for them to be secured to the pit. The sub-frame is installed when the pit precast is created. It has the great advantage of only being joined to the pit by welding, making it extremely easy to replace, move and/or change it by another machine.

The Inkema RH11 Dock Leveller is composed of three parts:

- The platform consists of a 6/8mm thick tear plate top, rolled steel sections and lateral toe guards.

- Compact and robust lip made of 13/15 mm thick steel tear plate. The lip is hinged, and its end is milled, allowing it to fit against the lorry perfectly and smoothing the lorry’s passage.

- The lower structure is made from rolled steel sections, and the platform and hydraulic group are installed on it.

All the Inkema Dock Levellers and loading bridges have been calculated and designed to follow European directives and standards.

The RH11 Dock Leveller has the following safety features:

- Emergency stop: Activated by switch or power failure.

- Fixed and movable to guards: Prevent feet from being trapped between the platform and the pit.

- Sidebands: Help reduce the risk of collisions.

- Safety bar: Prevents it from closing during maintenance.

- Anti-fall safety valves inside the hydraulic cylinder.

- Platform with anti-slip tear surface on top.